Delivery Management

Optimize shipping processes. Create efficiencies. Flexibility

Book and print | Order management | Carrier connections | Integrations

Commerce

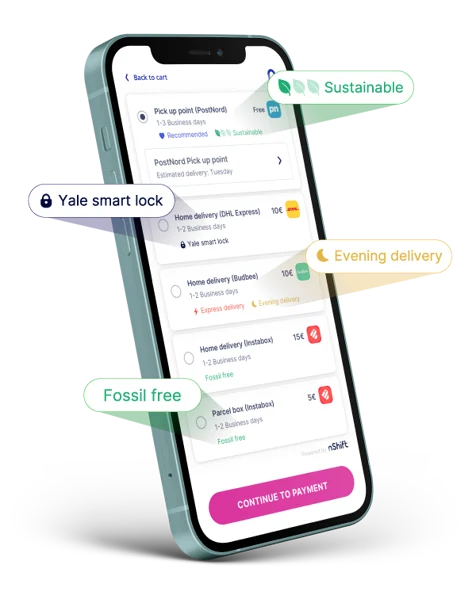

Increase cart conversions. Better customer experience. Build loyalty

Checkout | Order tracking | Returns management

Enabling multi-carrier delivery and experience management - from Checkout through to Returns

We are the global leaders in delivery management software. We help retailers, ecommerce businesses, warehouses and manufacturers to run more efficiently and to grow.

We invest heavily in developing new services so our customers can do more for their customers: to sell more, deliver better customer experience and build loyalty.

We enable retailers to provide a full range of delivery options, generate new revenue, lower implementation risk and offer sustainable delivery options. Underpinned by the world's largest carrier library.

We invest in the tools that drive growth that enables businesses to build capacity, manage sales peaks, and scale as they grow. An omnichannel experience, including e-commerce, buy in-store, deliver, and click and collect. Creating a seamless, one-click buying and delivery process.

Create an end-to-end delivery customer experience that builds loyalty

Our Misfits demo site gives you an insight into some of the features that enhance the customer experience with live versions of our Checkout, Track and Returns solutions.

Trusted by brands around the world to deliver real business impact

more revenue during e-commerce shop checkouts

integrations into e-commerce, ERP, WMS, and Payment Providers

of all returns become exchanges

carriers connected to ship anywhere

Driving value for our customers

By helping improve customer loyalty and the customer experience. Automate the entire delivery management process to ship anywhere.

Incremental revenue

Create new sales opportunities

Data-driven insight

Gain new information about deliveries

Better customer experience

Reduce support calls by up to 60%

Strategic growth enabler

Increase productivity with reduced handling and restocking times, and automated documentation

Brand reputation and loyalty

Repeat purchase and recommendation

Scale shipments globally

Deliver to 190+ countries

Lars Dige Pedersen also discusses the five pillars of driving value

Customer stories